LA Foods keeping a close eye on Port of Baltimore Bridge crisis

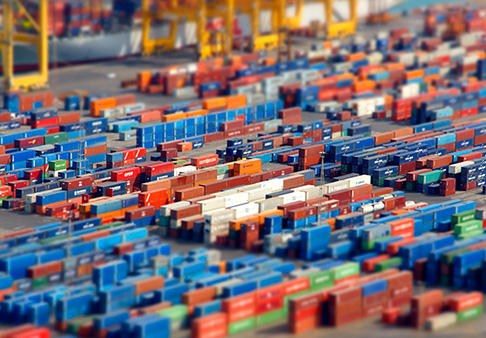

East Coast to Midwest buyers relying on goods shipped via the Port of Baltimore face potential cost hikes following the collapse of that city’s Francis Scott Key Bridge. The American Trucking Association estimates that 4,900 trucks daily, carrying an annual average of $28 billion worth of goods, will now require rerouting, escalating expenses for shippers and consumers alike.

“The Key Bridge and Port of Baltimore are vital elements of our nation’s supply chain,” emphasized the association, projecting significant and enduring repercussions for the region beyond the immediate tragedy. Hazardous material shipments, like diesel fuel, are particularly susceptible due to tunnel restrictions.

The closure will exact a toll on time, fuel, and delays for trucks traversing the region, amplifying the economic disruption inflicted by the Port’s shutdown, noted the association.

The Council on Safe Transportation of Hazardous Articles declined to comment on the situation, saying only that they urge state and federal authorities to expedite efforts to reopen the port and replace the bridge. Maryland Governor Wes Moore has moved to declare a state of emergency and President Joe Biden has pledged federal resources to immediately address the crisis.

For Baltimore, a primary entry point for agricultural and construction equipment destined for the Midwest, the situation will likely have critical impacts, especially for Midwest farmers during peak planting and machinery import season.

Abe Eshkenazi, CEO of the Association for Supply Chain Management, laments the compounding disruptions already straining a fragile system. “If this were the only issue, I think we’d be in a much better position,” Eshkenazi said.

With disruptions likely to persist, companies may redirect shipments to neighboring ports, incurring elevated freight costs and potential congestion. Tinglong Dai of Johns Hopkins Carey Business School anticipates a prolonged period for logistics normalization, anticipating elevated shipping costs in the interim.

While alternative routes, such as rerouting to the Port of Virginia, may alleviate some pressure, concerns remain over global shipping rates and supply chain vulnerabilities. Despite assurances from automakers like General Motors and BMW, the incident underscores the logistical challenges ahead, necessitating collaborative efforts to mitigate disruptions and safeguard operations.

Larry Schwartz, Director of Business Development for LA Foods, says “We will continue to monitor the situation. More importantly, at this time we feel heartbroken for the families of the victims and the people of Baltimore.”